Data Collection Software and Hardware

Data collection for the purposes of historical accuracy and security are imperative in industry today. At eNETDNC, we specialize in data collection from CNC and manual machinery at tool and die shops, machine shops and manufacturing facilities. Our system communicates directly with the machine and integrates with most client ERP systems providing data on jobs, part quantities, maintenance schedules and much more.

Data collection for the purposes of historical accuracy and security are imperative in industry today. At eNETDNC, we specialize in data collection from CNC and manual machinery at tool and die shops, machine shops and manufacturing facilities. Our system communicates directly with the machine and integrates with most client ERP systems providing data on jobs, part quantities, maintenance schedules and much more.

We will install systems that are compatible with all brands of CNC and manually controlled machinery using industrial grade components that are accessible from any part of the plant. The installed network provides features such as real-time monitoring, automated notification and alerts with network security protocols as standard in addition to many others. Power protection is also a consideration and we protect our system with up to 20kv surge protection, with system communication that is based on standard 802.11 Ethernet protocols.

Improved accuracy, operator accountability and increased production efficiency are just a few of the benefits that are achieved with this cost effective solution. We provide a single network solution often eliminating multiple duplicate systems.

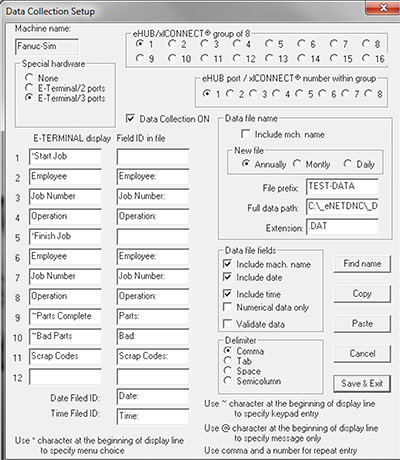

Compatible with any 32 and 64 bit Windows operating systems and using C++, a robust programming language, the system is completely customizable, incorporating, for example, optional bar code scanners and the addition of extra data inputs if required.

eNETDNC can simplify and make your data collection more effective. contact us or see the table below for a more detailed description of our services.

Data Collection Software and Hardware Specifications:

| Product Name | eNETDNC Data Collection |

| Function | Data Collection from CNC & Manual Machinery Communicates Job-Related Information Directly from the Machine Control |

| Hardware Features (eTERMINAL Addition) |

Industrial Grade Components Standard Cat-5 Cabling Surge Protection Up to 20 kV Made in the USA Bar Code Scanner (optional) Customizable |

| Software Features | Easily Integrates with most Client ERP Systems Based on Standard 802.11 Ethernet Plant-wide Accessibility Tapered User Access Capabilities Real-Time Monitoring Automated Notification/Alert System Compatible with All Brands of CNC and Manual Controls Compatible with Standard Network Security Automated File Compare Add-ons (Addition of any Data Inputs) |

| Inputs Examples | Employee Number Job Number Set-up Time Production Time Accurate Part Quantities Scrap Parts Scrap Codes Maintenance Scheduling Material Parts Maintenance Parts (Ex. Oil) |

| Language | C++ |

| Operating System Compatbility | All 32-Bit Microsoft Windows Systems All 64-Bit Microsoft Windows Systems Windows 98 Windows NT Windows 2000 Windows XP Windows Vista Windows 7 Windows 8 Windows 10 |

| Benefits | Increased Production Efficiency Data Acquisition on Machine Status Operator Accountability Improves Accuracy Captures Real World Data Expanded to Support Unlimited Number of Machines Supports all CNC Machine Control Types Eliminates the need for Duplicate Systems Wired Throughout the Shop Eliminates the need for Expensive Centralized Computer or Data Collection Stations on the Shop Floor Customizable ( Addition of any Data ) inclusion of Client Suggestions Configurable to any Shop Management or ERP System |

Additional Information

| Industry Focus | Machine Shops Tool & Die Shops Manufacturing OEM |