Machine Monitoring Software

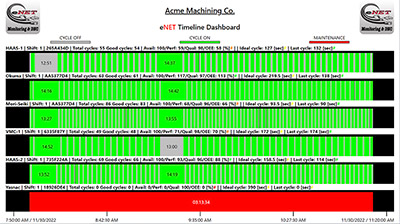

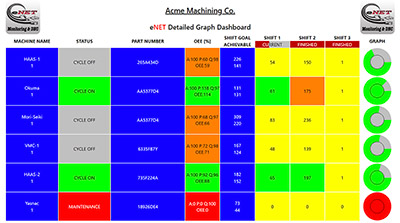

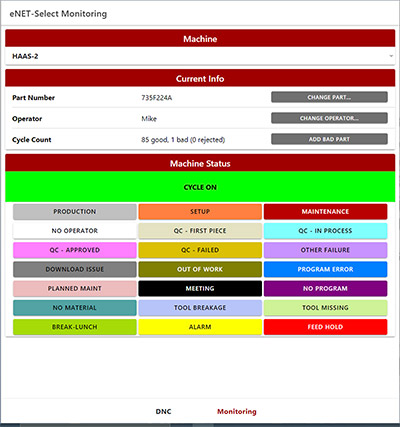

As the Midwest premier provider of machine monitoring solutions, eNET Machine Monitoring has empowered manufacturers for over 25 years with event driven machine utilization (OEE) data and real-time machine status visibility, to enhance production management decision-making. By leveraging secure locally hosted American-made machine monitoring software and hardware, eNET offers the most robust machine monitoring system on the market. Our new customers often tell us “Once eNET is in, it just works!” Not only can eNET automatically collect machine utilization data such as (cycle on/off, setup time, cycle time, etc.), our advanced software and hardware combine to provide the (Cycle Start Disable) feature, which forces machine operators to enter a downtime reason in order to unlock an idle machine.

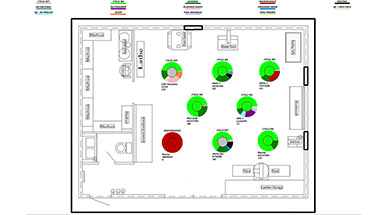

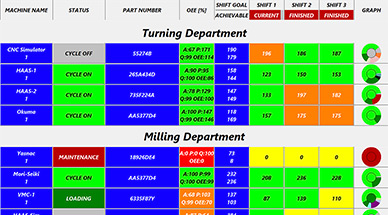

eNET Machine Monitoring is also the most versatile machine monitoring solution available, as it’s designed to be “the one system for the whole shop”. eNET offers the capability to monitor any type of machine including CNC machines, automated equipment sand even manual machines. Join the Smart Manufacturing revolution and gain valuable visibility into your manufacturing operations by leveraging eNET’s live machine monitoring dashboards, industry-leading monitoring reporting capabilities and the ability to dive deeper into your machine monitoring data. Your data can even be easily exported into 3rd party systems, such as ERP or MES softwares. There’s unrealized efficiency in your machines, and eNET will help you find it!

For further insights into our cutting-edge machine monitoring solutions, refer to the table below or reach out to us directly.

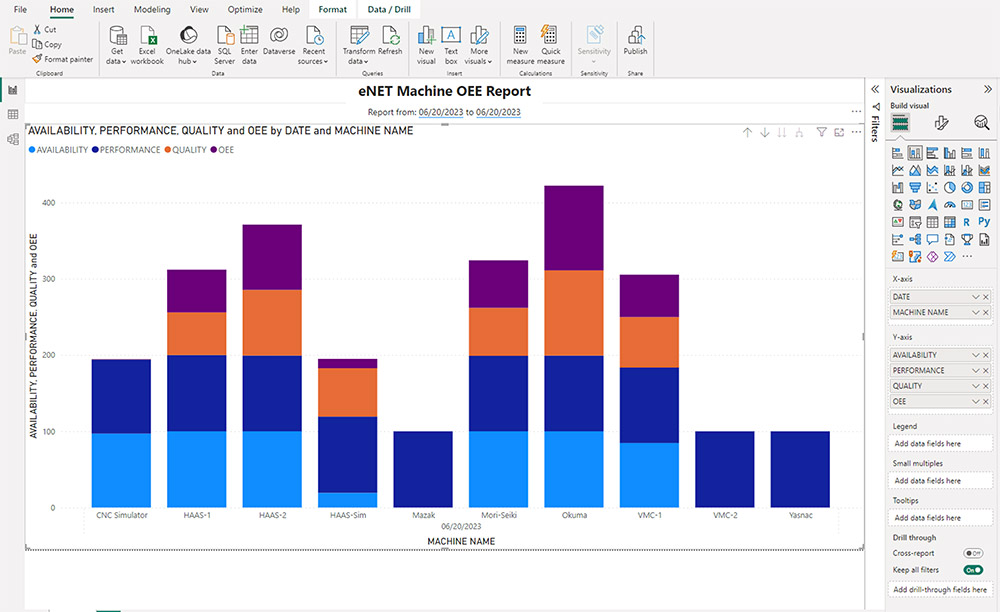

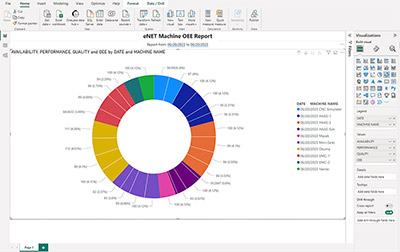

Just released, eNET Client is the smart manufacturing industry's most powerful & versatile Machine Monitoring Reporting and Machine Monitoring Data Explorer Software!

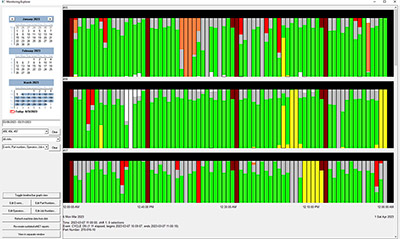

The eNET Client machine monitoring software allows users to automate and even totally customize Machine Monitoring Reports by leveraging a powerful new software from Microsoft called Power BI, which is built-into every seat of eNET Client. There is also an easy to use Machine Monitoring Data Explorer UI for deeper dives into your machine monitoring data, along with the password-protected ability for management to make edits to past events, part number, operator and job number machine monitoring data.

eNET web-based Machine Monitoring Softwares - eNET Select & Advanced HTTP eNET Machine Monitoring Dashboards

View all the web-based Machine Monitoring Softwares >

- Data I/O boards for collecting signals from machines such as Cycle On, Feed Hold, Spindle on/off, Feed Rate Override, Spindle Override, etc.

- 1 Serial Port for connection to wired or wireless eNET hardware, 1 Serial Port for CNC (optional).

- Ethernet Monitoring Boards for direct Ethernet Network connections also available.

- DB25 Connector, connects to - 8 Digital outputs, 2 Analog outputs, 1 Digital input. Multiple boards can be connected to a machine.

- Dimensions 3.375"W, .625"H, 4.5"L

CNC Machine Monitoring Software and Hardware Specifications:

| Product Name | CNC Machine Monitoring Solutions |

| Function | Real-Time Monitoring of CNC & Manual Machinery |

| Hardware Features | Industrial Grade Components Standard Cat-5 Cabling Surge Protection Up to 20 kV Made in the USA |

| Software Features | Based on Standard 802.11 Ethernet Plant-wide Accessibility Tapered User Access Capabilities Real-Time Monitoring Automated Notification/Alert System Compatible with All Brands of CNC Machinery Compatible with Standard Network Security Preventative Maintenance Tracking |

| Language | C++ |

| Operating System Compatbility | All 32-Bit Microsoft Windows Systems All 64-Bit Microsoft Windows Systems Windows 98 Windows NT Windows 2000 Windows XP Windows Vista Windows 7 Windows 8 Windows 10 |

| Benefits | Increased Production Efficiency Data Acquisition on Machine Status Operator Accountability |

Additional Information

| Industry Focus | Machine Shops Tool & Die Shops Manufacturing OEM |